Product Advantage

2. Computerized cam rotation system can be set from 0.1-359.9°, every two wire feeding wheels constitutes of one group, totally two groups.

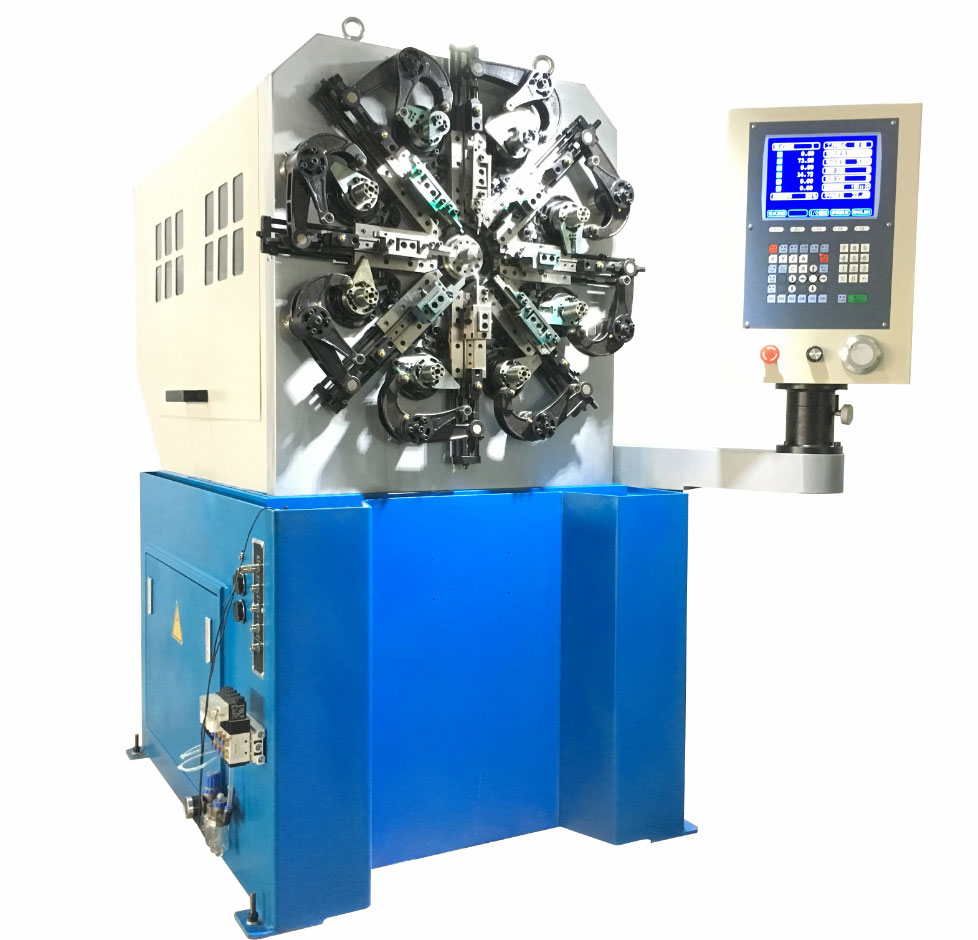

3. XD-CNC20D cnc spring machine is equipped with XinDing 3-4 axis spring machine controller. which can save 1000 files, axis location, feeding data.production speed and production output are displayed on the screen.

Technical Parameters

| Model: |

XD-CNC20D |

|

Wire diameter: |

φ0.3~2.3 mm |

|

Axes: |

3-4 axes |

|

Maximum Outside Diameter: |

40mm |

|

Maximum Feeding Length: |

unlimited |

|

Maximum Manufacture Speed: |

100pcs/min |

|

Feed Speed: |

200m/min |

|

Memory Number: |

1000pcs |

|

Wire Feed Servo Motor: |

2.7kw |

|

Cam Servo Motor: |

2.7kw |

|

Quin Servo Motor: |

0.75kw |

|

Power AC: |

3-phase 380v |

|

Dimensions (L*D*H): |

1400X550X1600mm |

|

Wooden Case Dimension: |

1600x600x1700mm |

|

Machine Weight: |

900kg |

|

Gross Weight: |

950kg |

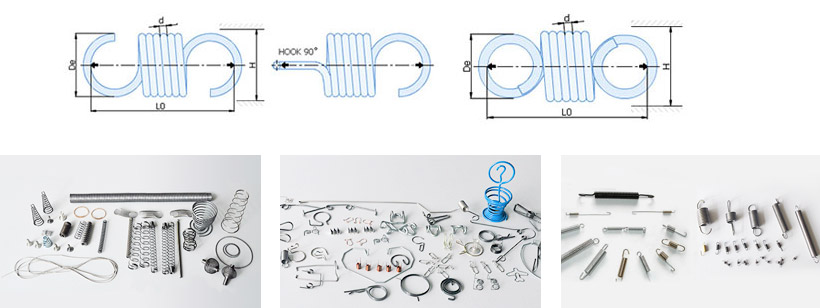

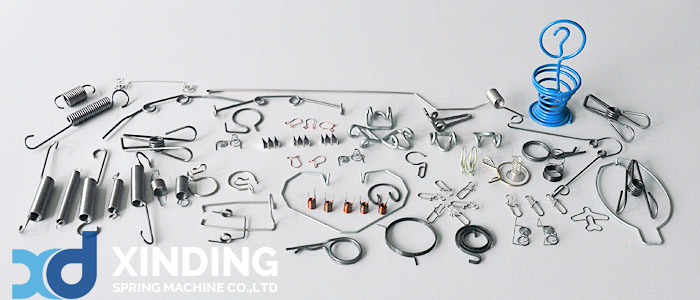

Sample Display

Video

Product Details

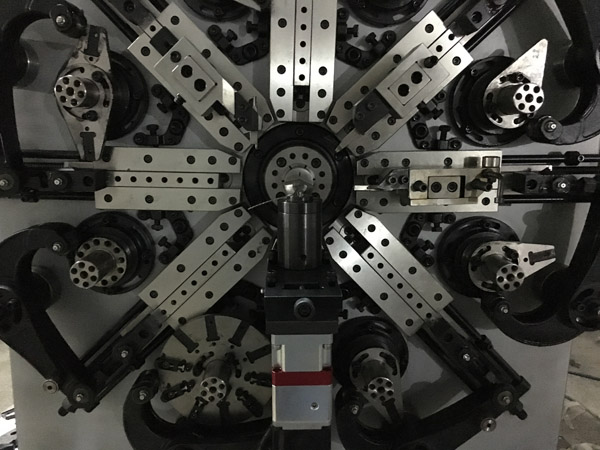

2. repeatable positioning accuracy up to±0.01mm.

3. Low failure rate,automatic alarm and fault indication,one-button reset function.

4. Adopting an integral frame structure, high strength, low distortion and durability.

5. Innovative design of great flexibility.

6. Patented and innovative time-line-basis spring program software.

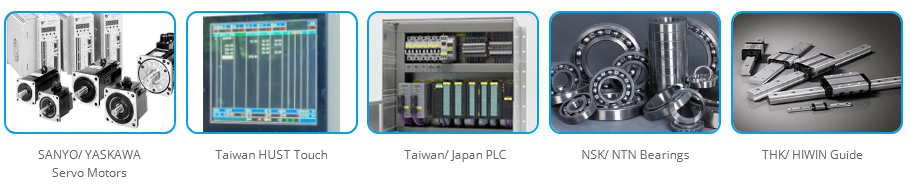

Use of famous brand components, ensures the stability of spring forming control system.

Manufacturability

Service Clients

Certifications

Success Cases

English

English

Español

Español

Pусский

Pусский

简体中文

简体中文