Product Advantage

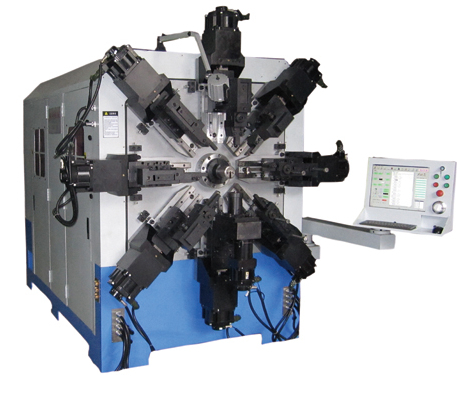

XD-1120 Eleven axis camless CNC Spring Forming Machine for forming wire

Special camless design equipped with free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

Advance attachments such as rotary wire, spinner, and the x-y free arm can be optionally equipped to the machine.

Intuitive graphics user interface.

Characteristic is due to the employment of a bullet proof software engineering methodology. This makes learning and configuring highly complex springs a simple task.

Commonly use in the industries of: automobile, wire forms, entertainment and fitness.

XD-1120 camless spring former

Technical Parameters

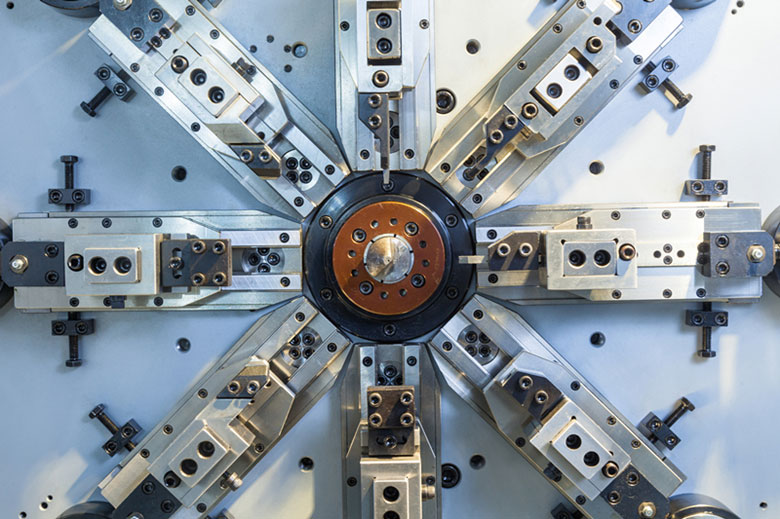

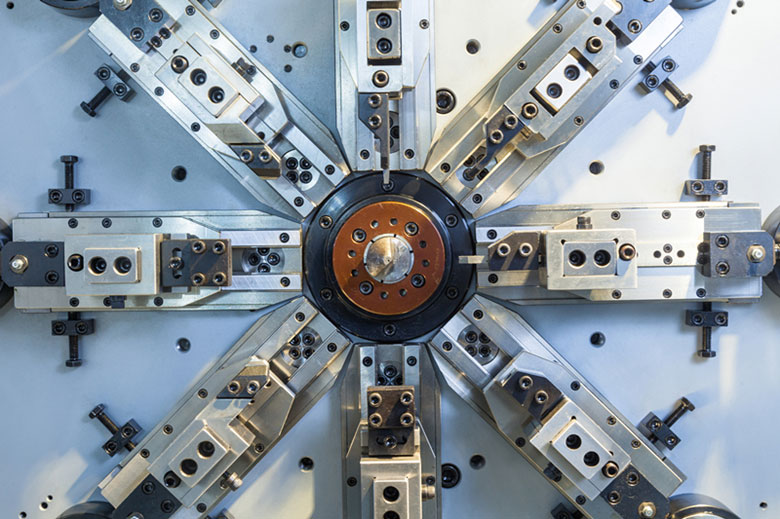

| 1.Axis count: | 11 axis | |

| 2.Wire size: | ¢0.30~2.0mm | |

| 3.Max outside diameter: | ¢40mm | |

| 4.Wire feed motor: | 2.7kw | |

| 5.Sliding arm motor×8: | 0.75kw | |

| 6.Quill motor: | 0.75kw | |

| 7.Spinner motor: | 0.4kw | |

| 8.Computer display: | Chinese/English | |

| 9.Max wire feed: | 99999.99mm | |

| 10.Min wire feed: | 0.02mm | |

| 11.Computer memory: | 500 programs | |

| 12.Dimensions: | 1450*550*1650mm | |

| 13.Weight: | 850kg | |

| 14.Power ac: | 3-phase 220v 50hz | |

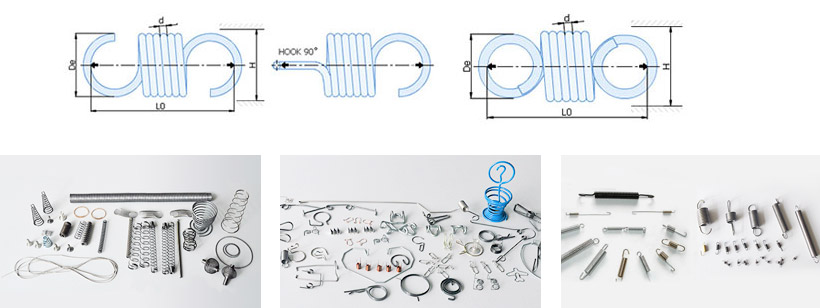

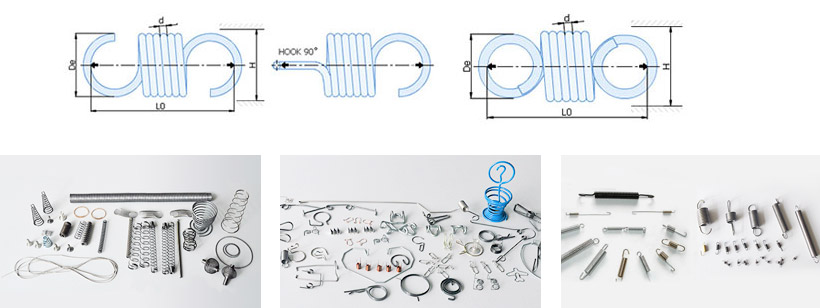

Sample Display

This CNC spring machine produce various ultra-precision irregular springs, compression springs, pulling springs, dual-torsion spring, flat line(spiral power spring)and line molding spring etc.

Video

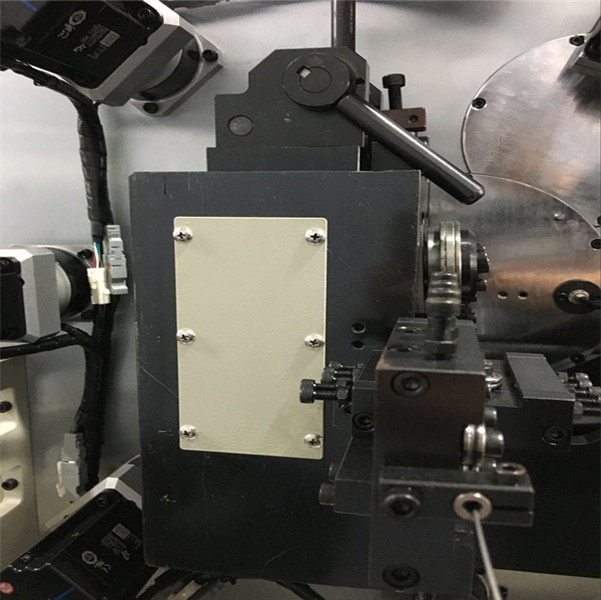

Product Details

1. Use servo control system to save energy 30-50 %.

2. repeatable positioning accuracy up to±0.01mm.

3. Low failure rate,automatic alarm and fault indication,one-button reset function.

4. Adopting an integral frame structure, high strength, low distortion and durability.

5. Innovative design of great flexibility.

6. Patented and innovative time-line-basis spring program software.

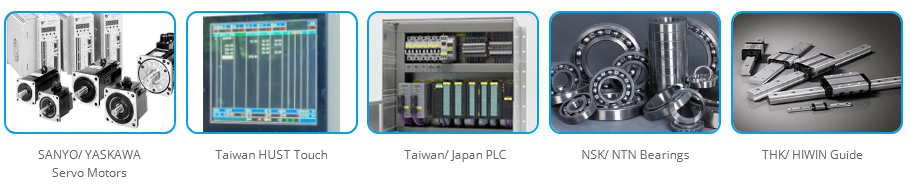

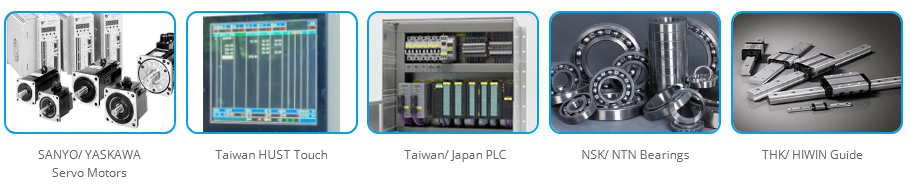

Use of famous brand components, ensures the stability of spring forming control system.

2. repeatable positioning accuracy up to±0.01mm.

3. Low failure rate,automatic alarm and fault indication,one-button reset function.

4. Adopting an integral frame structure, high strength, low distortion and durability.

5. Innovative design of great flexibility.

6. Patented and innovative time-line-basis spring program software.

Use of famous brand components, ensures the stability of spring forming control system.

Manufacturability

Service Clients

Certifications

Success Cases

English

English

Español

Español

Pусский

Pусский

简体中文

简体中文